Printing Catalogs ‚úĒCompany ‚úĒAdvertising.

Company catalogs: a key element of brand image and sales tool

In today's dynamic business world, companies are constantly seeking effective ways to stand out in the market and reach their customers. One of the most effective marketing tools that help achieve these goals is company catalogs. Contrary to what one might think, in the era of digitalization, printed promotional materials still play a significant role, offering a range of unique benefits.

Functions of company catalogs

Company catalogs serve many important functions in a company's marketing strategy:

- Presentation of Products and Services: This is the basic function of every catalog. Detailed product descriptions, high-quality photos, and technical information help customers better understand the company's offerings.

- Building Brand Image: A professionally designed catalog enhances the brand's image, showcasing its attention to detail, quality, and aesthetics.

- Sales Tool: Catalogs facilitate the sales process by providing sales representatives with necessary information in an attractive form.

- Customer Communication: Catalogs are also an excellent way to convey information about current promotions, new products, and other important company events.

The process of creating a company catalog

Creating a company catalog is a multi-step process that requires the collaboration of many specialists:

- Concept and Planning: At this stage, the goals of the catalog, its target group, and the overall graphic concept are defined.

- Collecting Materials: Gathering content such as product descriptions, photos, technical specifications, and other relevant information.

- Graphic Design: Designing the catalog layout, choosing appropriate colors, fonts, and graphic arrangement. It's important that the catalog is consistent with the company's visual identity.

- Composition and Printing: The technical stage where graphic material is prepared for printing. Choosing the right paper, printing technology, and finishing is crucial for the final effect.

- Distribution: Finished catalogs need to reach customers. They can be distributed at trade shows, mailed, or available at sales points.

Challenges and trends in the printing industry

The printing industry, like many other sectors, faces challenges resulting from technological advancements and changing consumer preferences:

- Personalization: Customized catalogs tailored to individual customer needs are becoming increasingly popular, requiring advanced printing technologies.

- Ecology: Growing environmental awareness among consumers influences the choice of materials and printing technologies. Companies are increasingly opting for recycled paper and eco-friendly inks.

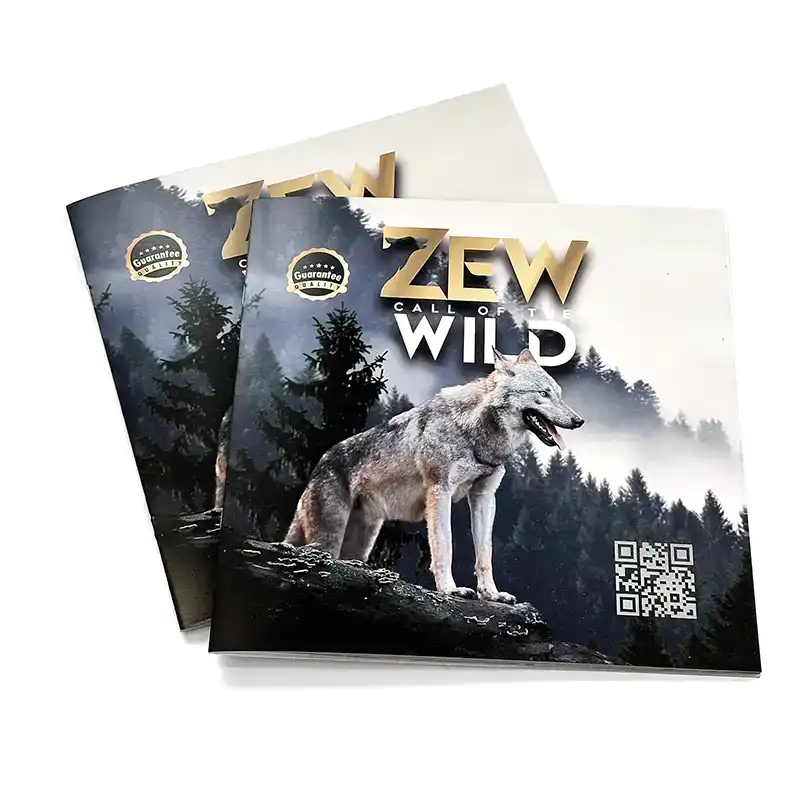

- Integration with Digital Technology: Modern catalogs often include interactive elements, such as QR codes, leading to additional online content.

The future of company catalogs

Although the business world is increasingly moving online, company catalogs still have a bright future. Printed promotional materials offer unique sensory experiences that are hard to replace with digital equivalents. Combining traditional catalogs with modern technologies can be key to success, merging the advantages of both worlds.

In summary, company catalogs are not only a tool for presenting offers but, above all, a powerful tool for building customer relationships and brand image. It is worth investing in their professional preparation to stand out from the competition and effectively reach the target group.

How to prepare a project for printing a catalog?

To print company catalogs, you need to provide a project in PDF/X-3 format made to the size of the ordered product's template. The project template and its description are available on the product configurator page.

Note, before downloading the template, configure your catalog as the template is dynamically created based on the pricing parameters. The catalog PDF should be prepared in the ordered product format, e.g., A4 without combining individual pages into sheets. The printing house, using automatic imposition software, assembles the printing sheet in a manner suitable for the catalog, considering spine compensation in the case of stitched binding.

How to prepare the spine of the catalog?

During design, an important aspect when choosing glued binding is the width of the catalog cover's spine. Due to production tolerances, it is best to design the spine in the cover color. In the case of a spine width greater than 1 cm, you can design additional text on it, such as the edition title.

The catalog configurator on the printing house's website automatically calculates the thickness of the printed catalog spine. After selecting the paper for the catalog's interior and specifying the number of pages, the system will automatically calculate the spine thickness in the cover section and generate a template for its preparation.

How do we print catalogs?

We provide company catalog printing in two different technologies, making our offer flexible and tailored to the client's needs. For print runs from 1 to several hundred copies, digital printing technology is used, while for print runs in the thousands, offset printing technology is used. We print catalogs in black and color on a wide range of papers. Popular paper combinations for catalog printing are 250-300g for the cover and 130-170g for the catalog interior. You can decide which paper combination to use for the catalog's interior and exterior or take advantage of our advice.

What enhancements do we apply to catalogs?

Enhancements significantly impact the aesthetic value and durability of printed company catalogs.

Overall Enhancements:

- Glossy lamination

- Matte lamination (regular, anti-scratch, soft-touch)

Selective Enhancements:

- UV varnishing (flat and raised)

- Gilding

- Silvering

What types of binding are used in catalogs?

Wire-stitched Binding:

In this type of binding, wire is used to join the pages, commonly seen in notebooks, hence the colloquial name "notebook binding." Wire-stitched binding is used for catalogs with a volume of 8 to several dozen pages (depending on the paper thickness). The spine in this binding has a gentle shape compared to glued binding. In wire-stitched binding, the number of catalog pages must be divisible by 4. This binding is less durable than glued binding because the pages are secured at only two points, not along the entire length. Wire-stitched binding is the cheapest available option.

Glued Binding:

The most popular type of catalog binding. The covers in glued catalogs are usually made of papers and cardboards with weights of 250-350g, similar in stiffness to business cards. Glued binding is used for catalogs with a volume of at least 60 pages. The catalog cover spine should be between 4 and 50 mm wide. Company catalogs with a small number of pages cannot be produced in this technology and require wire-stitched binding.

In glued binding, depending on the need, two gluing technologies are used: Hot-melt or PUR.

As a rule, both technologies involve using high temperatures to melt the glue. However, PUR glue does not have sufficient strength for further processing after cooling.

Hot-melt is the most popular method widely used in catalogs for decades. There are many varieties of glue in this technology, which is continuously improved. The latest types of hot-melt glue, using polymers, achieve flexibility and durability parameters similar to polyurethane glue, significantly increasing its use in bookbinding.

Hot-melt is characterized by a high bonding strength and a favorable production cost. It is suitable for soft and hardcover catalogs. Its significant advantage is the fast binding speed, which occurs immediately after the glue cools, allowing for further bookbinding processing and quick delivery of the finished product to the customer.

PUR (polyurethane adhesive) - Adhesive hardened during a time-consuming (48h) chemical reaction, achieving high flexibility and adhesion to all printing substrates. This offers tangible benefits when gluing catalogs with stiff coated paper inside. Thanks to the flexible glue bond, the catalog can be opened without pages falling out.

Spiral Binding:

Binding commonly used in various documentation, menus, catalogs, which will be intensively used. Thanks to perforated pages and the use of a metal spiral, pages of any stiffness can be easily turned, maintaining the flat character of the catalog. The absence of a spine allows the catalog to be folded in any way. This binding is very convenient to use. The option to choose spirals in different colors can be an additional decoration.

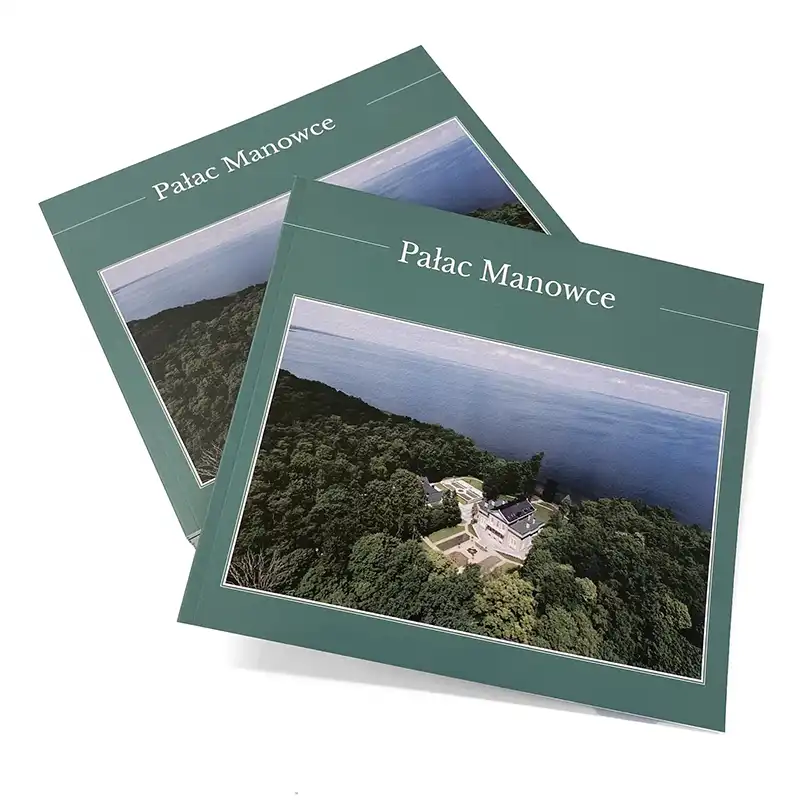

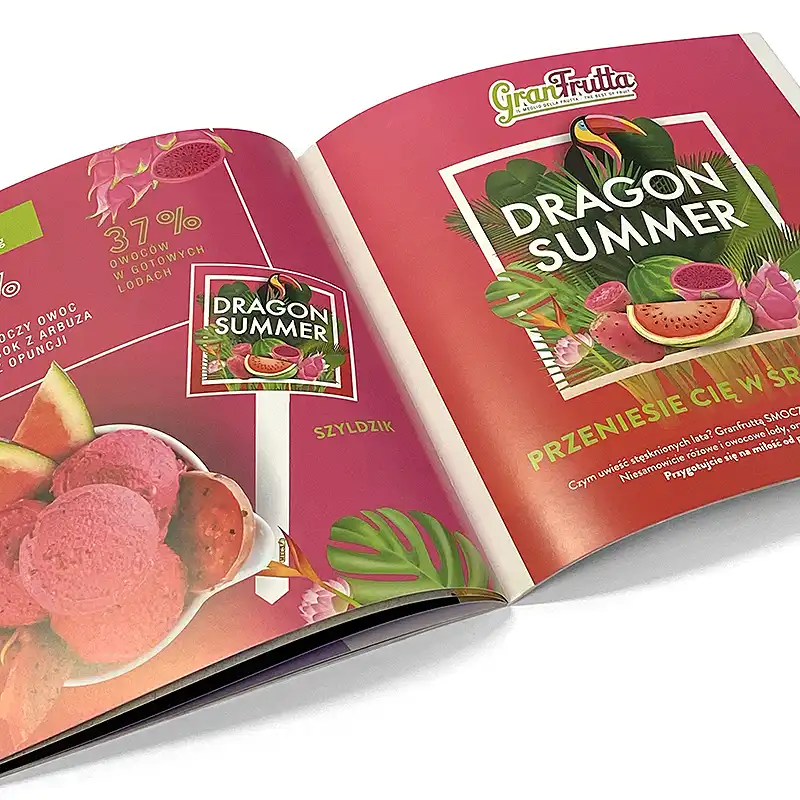

Square advertising catalog with perfect binding

Square advertising catalog with perfect binding

Square advertising catalog with perfect binding

Square advertising catalog with perfect binding

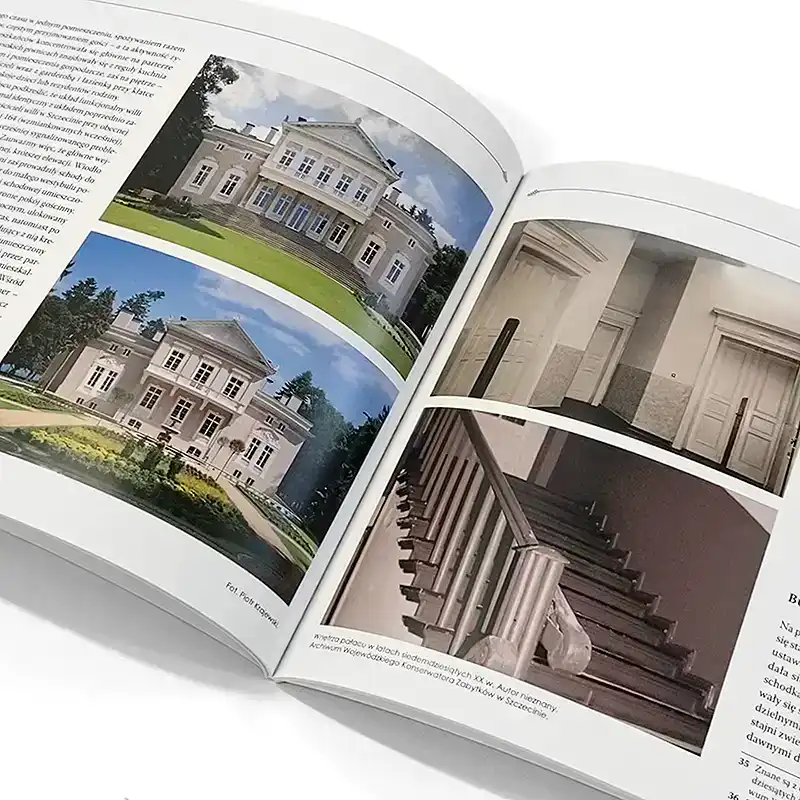

Product catalog with saddle-stitching

Product catalog with saddle-stitching

Product catalog with saddle-stitching

Product catalog with saddle-stitching

A4 advertising catalog with saddle-stitching

A4 advertising catalog with saddle-stitching

A4 advertising catalog with saddle-stitching

A4 advertising catalog with saddle-stitching

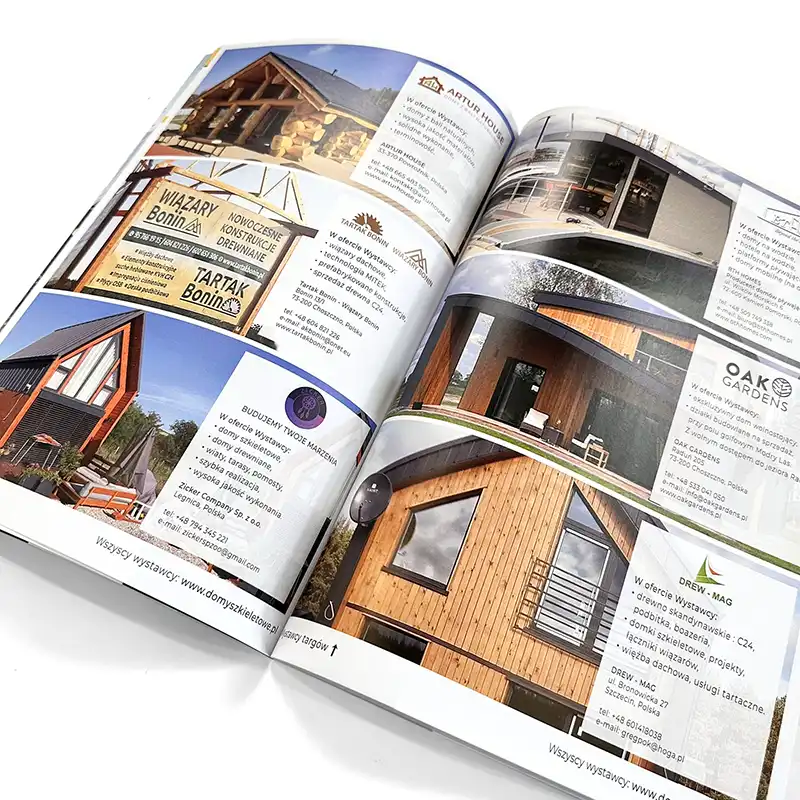

Square product catalog with saddle-stitching

Square product catalog with saddle-stitching

Square product catalog with saddle-stitching

Square product catalog with saddle-stitching