Description of options available for an additional charge in products:

- Die-cutting - machine cutting of a specific shape from paper.

- Punching, hole drilling - drilling holes of a specific diameter in clothing tags, notebooks, or binder cards.

- Finishing with aluminum strips - crimping decorative metal strips on two opposite edges, one of which may have a hole or hook for hanging.

- Corner rounding - trimming the corners of a product to give them a smooth shape, e.g., on labels, business cards.

- Scoring - a process of embossing a groove that allows easy folding of the paper at a specific point. Scoring is used on papers over 200g and cardboard. This process eliminates the risk of paper cracking during folding, as the paper is properly shaped at the groove.

For projects folded in a way other than commonly known (in half, C, Z, etc.), indicate in the comments field the position of the scores, specifying their distance in millimeters from the left edge of the paper. - Folding - machine folding (bending) of paper in a specific way. We distinguish between parallel and cross folds, e.g., C, Z, zig-zag, cross, window, altar fold, etc. Folding is used for soft papers with a weight not exceeding 170g. The folding process of thicker papers must be preceded by an additional scoring process.

- Pocket - a foil pocket glued to the product to store a CD, business card, etc.

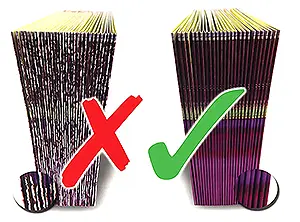

- Gluing in a block - gluing a specific number of sheets into a pad. The price of this process includes a cardboard base for the pad.

- Calendar block - a multi-sheet block containing individual months, used to build a calendar.

- Plastic window - a necessary element of the calendar for marking the current date.

- Perforation - a process of making micro-holes that allow easy folding or tearing of the paper at that point.

- Numbering - a process of applying unique numbers, codes, signs to each copy of the ordered print run.

- Cutting patterns from foil - surface cutting of self-adhesive foil to obtain specific patterns that can be peeled off.

- Teleaddress tear-off - cuts and perforation on the edge of a poster to obtain small business cards that can be torn off.

- Banner edge welding + eyeleting - preparing the banner for hanging, the banner is folded twice at the edges, welded, and eyeleted with aluminum rings.

- Gilding - embedding metallic foil into paper to achieve a mirror shine not available through traditional printing.

- Embossing - embossing a concave/convex mark, e.g., a logo, in paper to add a special visual effect.

- Coating with polyurethane resin - applying a special material on the surface of a sticker to create a raised effect.

- Gluing - assembling boxes, bags, or other products using glue or double-sided tape.