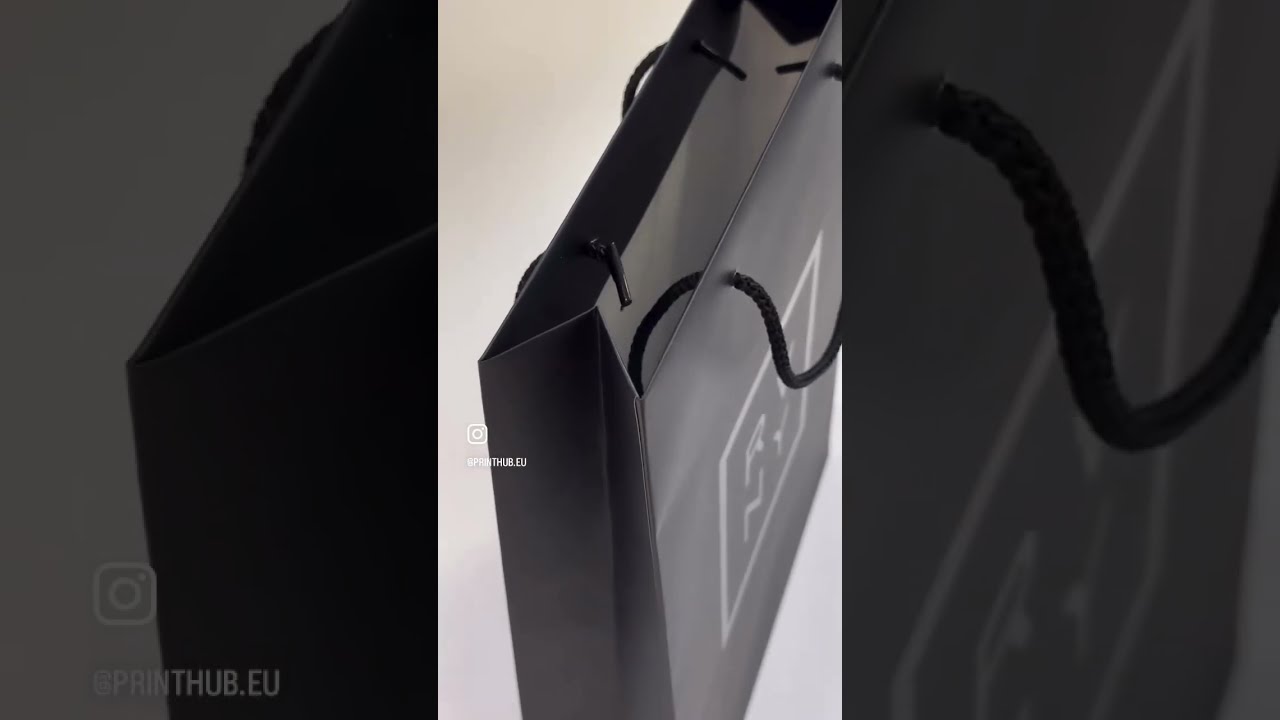

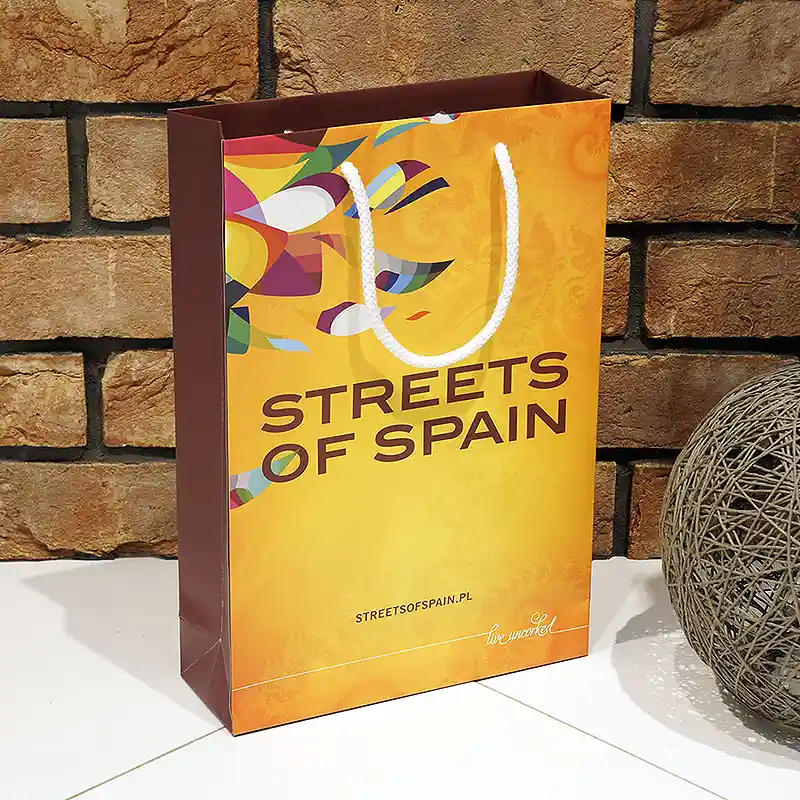

Matte laminated paper bag with an advertising print

Matte laminated paper bag with an advertising print

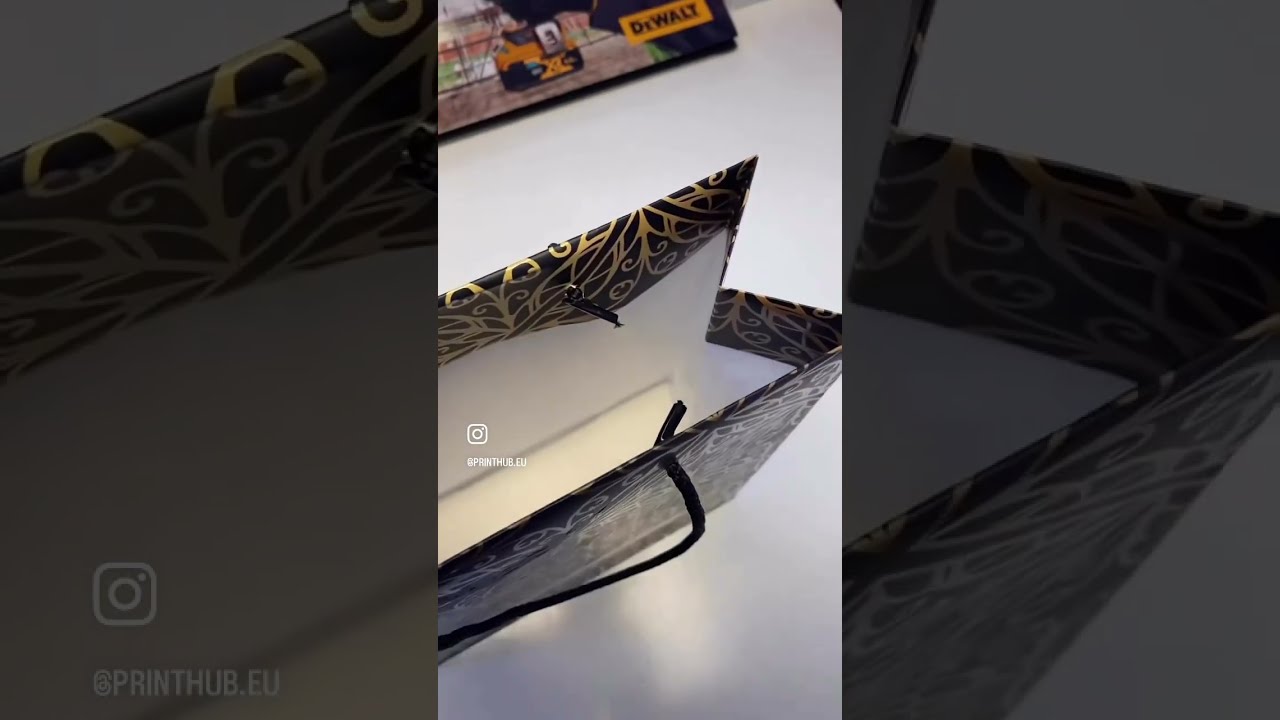

Laminated paper bag with print inside

Laminated paper bag with print inside

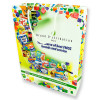

Matte laminated paper bag with full color print

Matte laminated paper bag with full color print

Matte laminated paper bag with full color print

Matte laminated paper bag with full color print

Impressive matt laminated advertising bag in blue

Impressive matt laminated advertising bag in blue

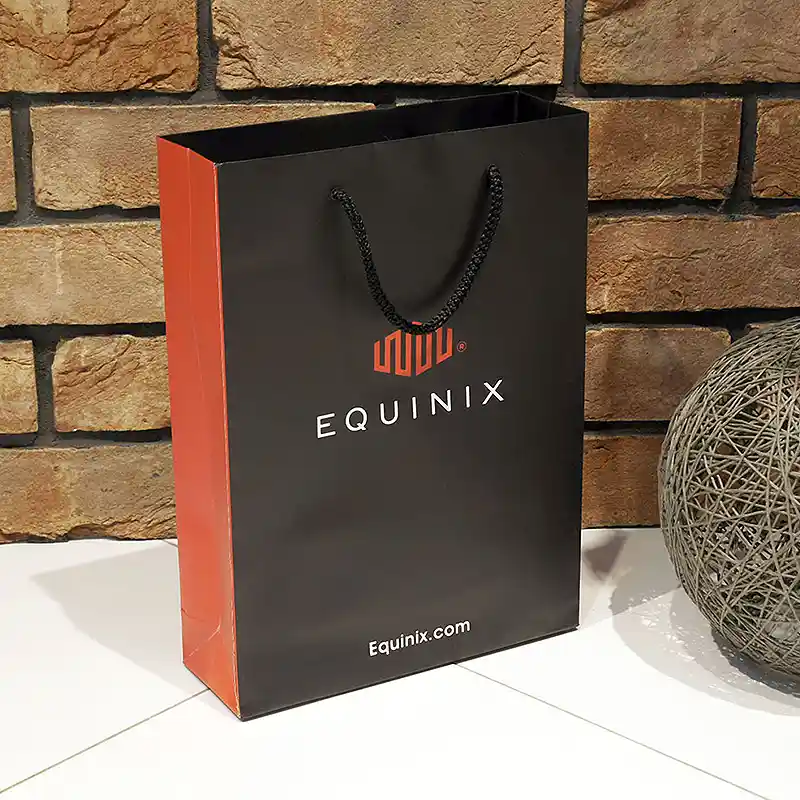

Impressive laminated advertising bag with a black front and red side

Impressive laminated advertising bag with a black front and red side

Impressive paper bag with a Pantone print

Impressive paper bag with a Pantone print

Paper bag when folded flat for transport purposes.

Paper bag when folded flat for transport purposes.

Comparison of the finish effect of laminated paper bags.

Comparison of the finish effect of laminated paper bags.

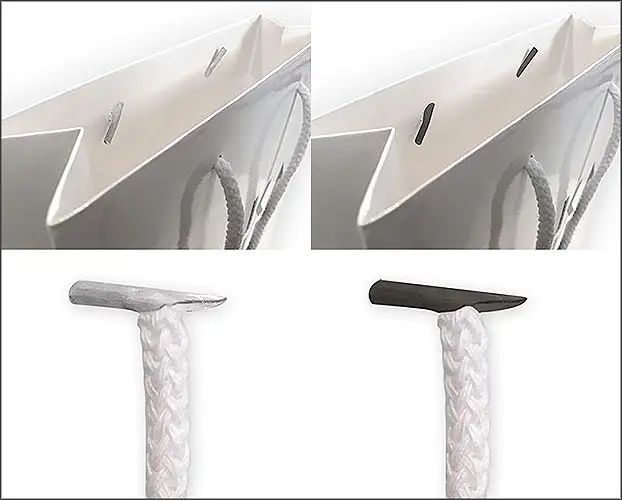

T-lace ends on the handles of paper bags

T-lace ends on the handles of paper bags

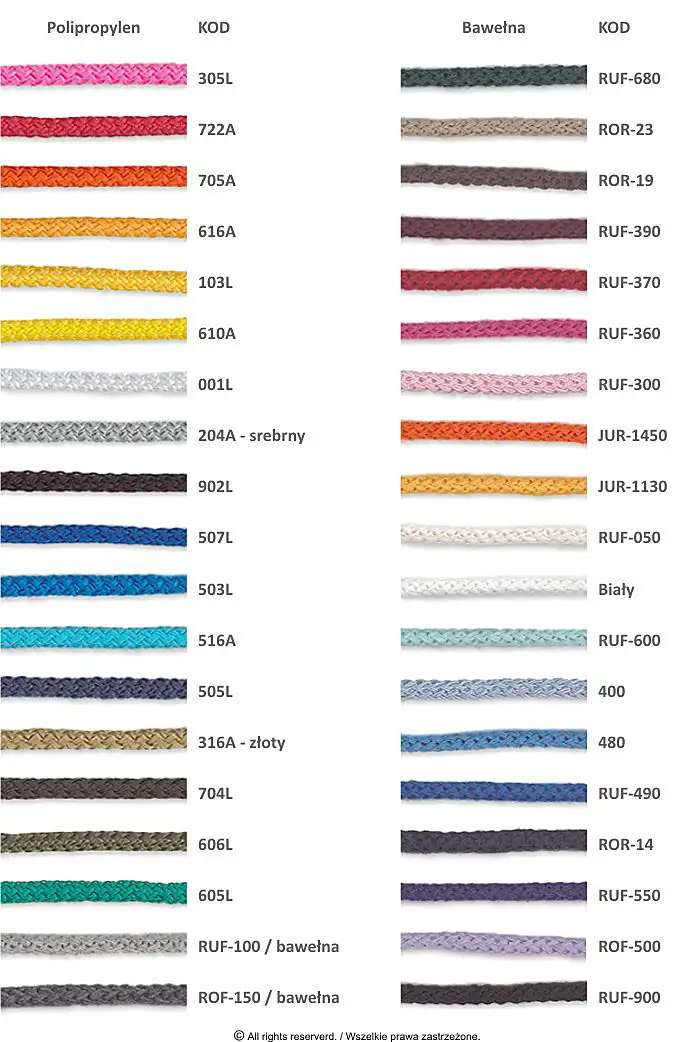

Pattern of strings used for the production of handles for laminated paper bags.

Pattern of strings used for the production of handles for laminated paper bags.

Laminated paper bags with printed Logo

✓exclusive ✓luxurious ✓promotional ✓customized ✓full-surface print ✓produced from scratch.

Promotional laminated paper bags:

Key to building brand recognition and prestige

In today's world, where marketing and branding play a crucial role in shaping company images, promotional laminated paper bags have become an indispensable promotional tool. Thanks to their versatility, aesthetics, and customization options, these bags are gaining increasing popularity among entrepreneurs from various industries.

Multiple Uses and Mobile Advertising

One of the biggest advantages of laminated paper bags is their durability, which allows for repeated use. The sturdy construction and lamination make these bags resistant to mechanical damage and moisture, allowing them to be used multiple times, passing from hand to hand. Each use of such a bag is an opportunity to promote the brand in different places – in the office, on the street, in public transport, or during shopping. Thus, the laminated bag becomes a mobile advertising medium, reaching a wide audience.

Representativeness and Versatility of Use

Laminated paper bags are not only practical but also exceptionally representative. The aesthetic appearance, which can be further enhanced with various finishing techniques, makes holders eagerly use them for various purposes – not only as shopping bags but also as elegant packaging for gifts, documents, or promotional materials during conferences and events. Thanks to this, these bags find applications in many industries, such as fashion, cosmetics, technology, as well as in organizing various events, from trade fairs to corporate ceremonies.

Customization: The Key to Uniqueness

One of the most important aspects of laminated paper bags is the possibility of full customization. Entrepreneurs can tailor the bags to their needs by choosing the color of the handles, the type of lamination (matte, gloss), as well as additions such as selective varnish or gilding. Customization also includes prints – company logos, advertising slogans, graphics, or photos, which make the bag not only a functional packaging but also a carrier of aesthetic values and brand information. Thanks to this, these bags become unique and stand out from other promotional materials.

Building Brand Recognition and Prestige

Laminated paper bags are an excellent tool for building brand recognition and prestige. Thanks to high-quality workmanship and an aesthetic appearance, these bags attract attention and create positive associations with the brand. Each bag is a kind of "walking" advertisement that subtly promotes the company and its products. High quality and attention to detail translate into the image of the brand as professional and caring for its customers.

Summary

Promotional laminated paper bags are an investment that brings measurable benefits. Their durability, aesthetics, and full customization options make them an extremely effective marketing tool that helps build brand recognition and prestige. The versatility of use and representative character of the bags make them eagerly used by customers, which additionally increases the reach and effectiveness of promotional activities. In an era where brand image is key, laminated paper bags are an excellent support in building a strong and recognizable brand.

Exclusive laminated paper bags production

Printed paper bags are an important part of our offer. We produce paper bags in many shapes and sizes with the utmost precision and attention to detail. In each production, we ensure that the print meets high standards and that the bag looks great and is durable. Exclusive laminated paper bags produced in our printing house meet the high demands of customers from Poland and Western Europe. Many years of cooperation and timely deliveries of printed bags in consistently high quality guarantee the stability of cooperation with our partners.

What makes our bags stand out?

The distinguishing feature of our laminated paper bags compared to cheap market offers is the craftsmanship. We glue the advertising bags from pre-printed paper using offset technology according to the client's design. This allows for printing from edge to edge of the paper bag without any limitations. It is important to distinguish our laminated printed bags from low-quality prints made on already finished Chinese bags. Thanks to this decisive difference and the ability to configure many bag details, our paper bag looks exactly as the client wanted.

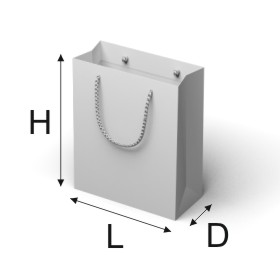

What sizes of bags do we offer?

The standard offer of the printing house includes over 40 sizes of laminated paper bags. The printing house also offers the production of laminated paper bags in non-standard sizes. On the website, there is a special configurator for non-standard bags, which allows you to calculate the production cost of a bag made in a different size than the standard offer. Laminated printed bags produced in a non-standard format have an extended delivery time due to the need to develop a new product.

What paper do We use for producing printed bags?

For the production of laminated paper bags, we use high-quality, triple-coated matte paper of 200g. The paper used for the production of bags is selected to meet the highest aesthetic and durability requirements. Upon individual order, it is possible to use thicker paper, e.g., 250g. Changes in this regard are individually negotiated, taking into account other parameters of the laminated bag.

How Is the printing on paper bags done?

Printing of laminated paper bags is done using offset technology, ensuring the highest quality and exclusive appearance of the bag. Prints with full coverage are not a problem as our machines are equipped for this task.

Available printing options for bags:

- Color printing CMYK Euroscale (photos, graphics, logos, etc.).

- Printing with special Pantone colors (gold, silver, others not available in CMYK).

Where Can the Print Be Located?

- Print on the outside - the entire surface of the paper bag inside.

- Print on the outside and inside - the entire surface of the paper bag inside and outside.

What are the finishing options for paper bags?

- Glossy foil lamination - provides vibrant colors and high contrast.

- Matte foil lamination - provides a subdued, soft effect, colors are less intense, and contrast is lower.

- Matte anti-scratch foil lamination - as above but more resistant to scratches.

- Matte soft-touch foil lamination - as above but with a soft touch surface.

- Matte foil lamination + selective gloss varnish on selected details - a popular combination giving an effective contrast between high gloss varnished elements and matte laminated foil elements.

- Printing inside the bag - to enhance the prestige of the laminated bag, internal printing may be a good choice.

What reinforcements do we use in the produced bags?

We use reinforcements from GC2 350g cardboard for the bottom of the bag and the upper strip where the handles are installed, ensuring that the bag can withstand a load of 10 kg. (confirmed in tests).

What are the nandles of the bags made of?

The handles in laminated bags are made of cotton or polypropylene string. The printing house offers a wide selection of handle colors to choose from. The ends of the handles are crimped with aesthetic T-lace tips in black or transparent (similar to shoelace ends), replacing unprofessional-looking popular knots. The length of the handles in the bags is standardized, but it is possible to make handles of special length on request.

How are laminated bags packed and shipped?

Finished laminated paper bags are packed flat in strong 5-layer cardboard boxes, ensuring safety during transport. Depending on the size of the order, for safety and economic reasons, laminated bags are shipped in boxes or stacked on a pallet.

Available delivery options:

- Courier

- Pallet shipping.

Shipping methods for paper bags:

- To the ordering party.

- Neutral to the end customer (ordering party = sender).

How to prepare a araphic design for printing paper bags?

To print a laminated paper bag, a graphic design in PDF/X-3 format based on the project template available with the bag configurator should be provided. After developing the project for printing, the PDF document should be delivered without the template described on the proper graphics because the project will be printed exactly as it was delivered. If creating a graphic design for the laminated paper bag print is problematic, our graphic studio will prepare the appropriate graphic design for you.

In case of any questions, feel free to contact us; we will gladly provide detailed answers to all of them at our e-mail.

We invite you to cooperate!