Selective UV varnish

Selective UV varnishVarnishing

- Offset varnish glossy or matte - applied in offset technology (the same as printing), mainly used as a protection for the print from smudging or rubbing, and also to enhance the aesthetic value of the product. Offset varnish gives the entire page a uniform matte or glossy finish, eliminating unwanted gloss of ink on a matte substrate. Offset varnish is the cheapest form of protection for the printed surface.

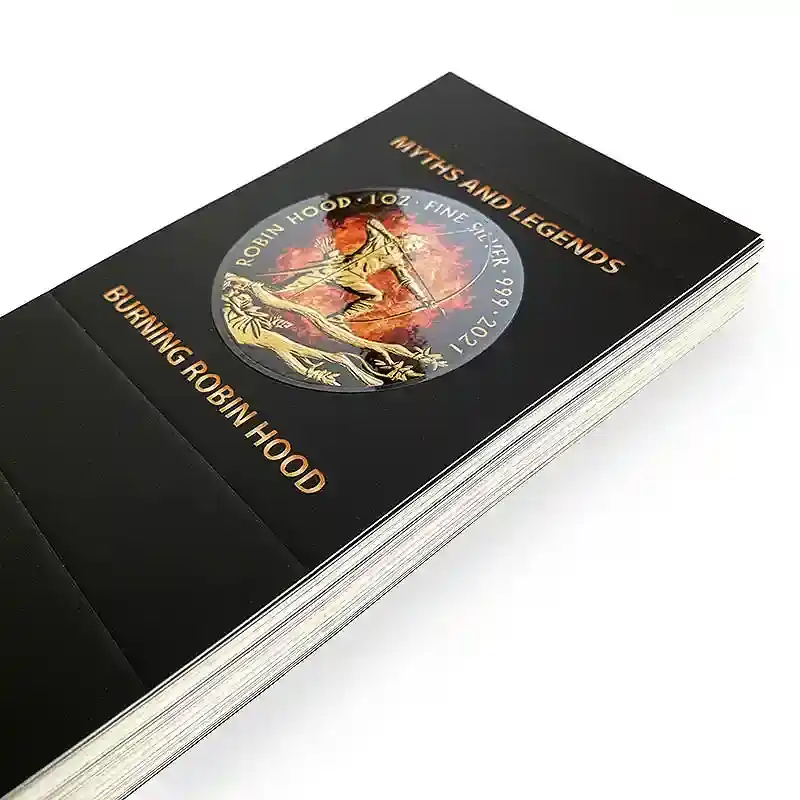

- Spot UV varnish - applied in screen printing technology, cured with UV radiation, it is hard and has a very high gloss (much higher than offset varnish). The main use of this varnish is to decorate selected parts of exclusive promotional materials. UV varnish, when applied to selected areas, gives them high gloss. For the best visual effect, UV varnish should be combined with matte lamination.

Preparing a mask for spot varnish:

- duplicate the project page of the work intended for varnishing

- convert all elements of the project that are to be glossy to black

- remove the remaining elements of the project

- save the prepared work as a PDF

- the result should be a PDF file in which the printed page is first and the mask is second

- in the case of multi-page work, the printed page and varnish mask must alternate.